Illuminating the Future- How Quantified Energy is Revolutionizing Solar Inspection

Vertex Holdings17 Jul 2025In the dead of night, while most of the world sleeps, a fleet of autonomous drones takes to the skies above solar farms across Asia, Europe, and the Middle East. These aren't ordinary surveillance drones—they're equipped with specialized cameras using electroluminescence technology that can peer inside solar panels, revealing hidden defects invisible to the naked eye. This is the cutting-edge world of Quantified Energy, a Singapore-based deep-tech company invested by Vertex Ventures SEA & India that's transforming how we maintain and optimize the world's rapidly expanding solar infrastructure.

The Birth of a Vision

The story of Quantified Energy begins not in a Silicon Valley garage, but in the laboratories of the Solar Energy Research Institute of Singapore (SERIS) at the National University of Singapore. Here, a team of researchers led by co-founder Dr Wang Yan spent their days testing new solar panels for manufacturers, evaluating quality in controlled lab conditions. But something kept happening that would eventually spark a revolution in solar inspection technology.

"We started getting repeated requests from developers and asset owners asking, 'Can you help check the condition of panels already installed in the field?'" recalls the QE team.

The problem was clear: sending panels back to the lab for testing was prohibitively expensive and time-consuming. After hearing this plea "again and again," the researchers realized they were sitting on a massive market opportunity. What if, instead of bringing panels to the lab, they could bring lab-grade diagnostics directly to the solar farm?

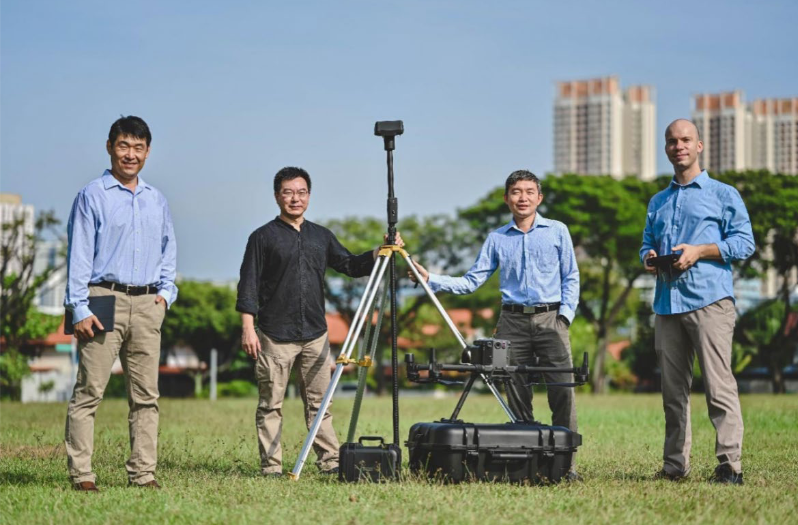

This question became the foundation of Quantified Energy, officially spun off from SERIS in 2021 with a bold mission: to make solar inspection smarter, faster, and scalable using drones and artificial intelligence.

A Solar Revolution in Need of Solutions

To understand why Quantified Energy's innovation matters, consider the staggering scale of global solar deployment.

Every second—yes, every single second—approximately 40 new solar panels are being installed somewhere in the world. By 2035, more than 15 billion panels will be operational globally, each designed to last 30 years. But here's the catch: they'll only achieve that lifespan if properly maintained.

The numbers paint a picture of explosive growth. In 2024 alone, the world installed a record 597 GW of solar capacity, representing a 33% surge over the previous year. China led the charge with 329 GW (55% of global installations), while India saw installations grow by 145% annually, adding 30.7 GW. The global solar market is projected to grow from 2.35 thousand gigawatts in 2025 to 6.26 thousand gigawatts by 2030, at a compound annual growth rate of 21.64%.

Yet this rapid expansion brings significant challenges. A single underperforming panel can reduce the output of an entire section of a solar system due to how panels are connected in series. Traditional inspection methods—primarily visual checks and infrared thermography—can only detect surface-level issues, missing many internal defects that silently drain system efficiency. With inspection costs ranging from $200 to over $1,000 depending on the technology and system size, asset owners need solutions that deliver maximum value for their maintenance investments.

The X-Ray Vision of Solar Panels

Quantified Energy's breakthrough lies in adapting a technology called electroluminescence (EL) for field use. "Think of it like this—just as doctors use X-rays to look inside the human body, we use electroluminescence to look inside solar panels," explains Dr Wang.

The science is elegantly simple yet powerful. During normal operation, solar panels convert light into electricity. EL testing reverses this process: by injecting a small electrical current into the panel at night, it causes the silicon cells to emit a faint light, similar to a dim LED. The pattern and intensity of this light reveal a wealth of information about the panel's internal health—cracks, broken cells, poor solder connections, and other defects that would otherwise remain hidden.

While EL testing itself isn't new—it's been a trusted laboratory technique for years—what makes Quantified Energy revolutionary is how they've automated and scaled it. Previously, EL testing required manual inspection of individual panels in controlled environments. QE has liberated this technology from the lab, mounting specialized EL cameras on autonomous drones that can scan entire solar farms in a single night.

The advantages over traditional methods are substantial. While infrared thermography can only detect temperature variations on the panel surface, EL imaging penetrates deep into the panel structure, revealing microcracks, cell fractures, and connection issues that don't yet show thermal signatures. Visual inspections might spot obvious damage like broken glass or discoloration, but they're blind to the internal degradation that accounts for most performance losses over time.

From Lab to Sky: The Evolution of Drone-Based Inspection

Quantified Energy's journey from concept to commercial deployment showcases the challenges and triumphs of deep-tech innovation. Their first-generation drones proved that autonomous EL inspection was not just possible but practical, with successful deployments across diverse environments from the humid tropics of Southeast Asia to the arid deserts of the Middle East.

But the team quickly realized that to achieve their vision of global scale, they needed a different approach. "We saw that scaling this globally would require a more flexible and partner-friendly approach," the QE team explains. This insight led to the development of their second-generation system, which represents a paradigm shift in how inspection technology is deployed.

Rather than manufacturing and operating their own drone fleet worldwide, QE developed a modular system that works with widely-used commercial drones like the DJI Matrice 350. They provide the specialized EL camera and their proprietary QEpilot software, which orchestrates the entire inspection process—from flight path planning to camera settings and data capture. Local drone operators in different countries can now offer EL inspections powered by QE's technology without the company needing a physical presence on-site.

This decentralized model is genius in its simplicity. It leverages existing drone infrastructure and operator networks while maintaining QE's technological edge through their cameras, software, and data analytics platform. It's how a startup from Singapore can inspect solar farms in Germany, analyze installations in India, and optimize operations in the UAE—all without leaving their headquarters.

The Digital Twin Revolution

What happens after the drones complete their nighttime missions is equally impressive. The captured EL images are processed into high-resolution, interactive maps that function like "Google Maps for solar farms." Asset owners can log into QE's client portal and explore their entire installation at multiple levels of detail—from bird's-eye views of the whole site down to individual panel health scores.

This digital twin approach transforms raw inspection data into actionable intelligence. Maintenance teams can identify exactly which panels need attention, plan efficient repair routes, and prioritize interventions based on severity and impact. For a 100-megawatt solar farm with over 300,000 panels, this level of granular insight was previously impossible to achieve cost-effectively.

The platform's AI engine plays a crucial role, automatically detecting and classifying defects with high confidence. But QE hasn't abandoned human expertise—for critical cases, their solar experts review and validate the AI's findings, ensuring accuracy and reliability. This hybrid approach combines the speed and consistency of artificial intelligence with the nuanced judgment of experienced professionals.

Market Forces and Future Horizons

The timing of Quantified Energy's innovation couldn't be better. The solar industry is experiencing unprecedented growth, driven by improving economics, climate commitments, and energy security concerns. The cost of solar electricity has plummeted by 90% over the past decade, making it the cheapest source of power in many markets. Yet as installations proliferate, the operations and maintenance (O&M) sector is struggling to keep pace.

Industry reports project the global solar O&M market will grow from $9.4 billion in 2024 to over $18 billion by 2030. This growth is fueled not just by new installations but by the aging of existing solar assets that require more intensive maintenance as they approach mid-life. The emergence of new international standards, particularly IEC 62446-4 which mandates detailed module-level inspections, will further drive demand for advanced inspection technologies like drone-based EL.

"The industry is clearly moving toward digital operations, automation, and predictive maintenance—and that aligns perfectly with what we do," notes the QE team. They see their technology as part of a broader transformation in how renewable energy assets are managed, moving from reactive repairs to proactive optimization.

Looking Ahead: The Next Chapter

As Quantified Energy looks to the future, several exciting developments are on the horizon. The company is exploring integration with other digital tools in the solar ecosystem, from performance monitoring systems to computerized maintenance management software (CMMS). They're investigating how machine learning can not only detect current defects but predict future failures, enabling truly preventive maintenance.

There's also potential for expansion beyond traditional solar farms. Rooftop solar installations, floating solar arrays, and even building-integrated photovoltaics could benefit from drone-based EL inspection, though each presents unique technical challenges. The company is also eyeing adjacent markets—could their imaging technology and analytics platform be adapted for wind turbine blade inspection or other renewable energy applications?

The integration of emerging technologies offers additional possibilities. As drone technology advances with longer flight times, better cameras, and improved autonomy, QE's inspection capabilities will expand correspondingly. The rollout of 5G networks could enable real-time data transmission and analysis, allowing for immediate decision-making during inspections. And as artificial intelligence becomes more sophisticated, the accuracy and insights derived from EL imaging will only improve.

A Bright Future for Solar Maintenance

Quantified Energy's story is more than just a tale of technological innovation—it's about recognizing a fundamental need in our transition to renewable energy and developing an elegant solution. As we collectively work toward a future powered by clean energy, the ability to maintain and optimize our solar infrastructure becomes increasingly critical.

As those drones continue their nightly flights, silently scanning solar farms under starlit skies, they're doing more than just collecting data. They're helping to secure our renewable energy future, one panel at a time. And in a world racing to decarbonize, that's a mission that truly matters.

The next time you see a solar farm gleaming in the sun, remember that its continued performance might just depend on the watchful eyes of drones and the innovative spirit of companies like Quantified Energy, working tirelessly to keep our clean energy infrastructure running at its best. In the grand narrative of the energy transition, they may not be the most visible players, but they're certainly among the most essential.

/f/233941/1280x720/0f0e470217/qe-thumb.jpg)